Explore The Fascinating History Of The 1966 Ford GT40

The 1966 Ford GT40 ‘s victory at Le Mans marked a turning point in racing history. With innovative engineering, powerful performance, and strategic decisions, Ford’s GT40 overcame Ferrari, proving American automotive prowess on the world stage.

Key Takeaway:

- The 1966 Ford GT40’s history is defined by its strategic design choices, technological innovations, and resilience, which led to its historic victory at Le Mans. Ford’s commitment to power, precision, and endurance reshaped American motorsport and engineering.

In 1966, Henry Ford II’s dream of toppling Ferrari at Le Mans became reality, thanks to the Ford GT40 Mk II. This historic victory was the culmination of three relentless years of development, experimentation, and sheer determination. With Ford securing an incredible 1-2-3 finish at the 24 Hours of Le Mans, American engineering had finally conquered the European racing stronghold.

The GT40 Mk II’s success lay in Ford’s strategic decisions to prioritize power and durability. Rather than opting for a lighter, high-revving 289 engine, Ford went with a 7.0-liter V8 for the Mk II. This choice wasn’t about speed alone—it was a calculated move to ensure reliability over the grueling 24-hour endurance race. The robust V8, though heavier and slower to rev, provided consistent power and could withstand the race’s punishing demands better than the lighter engines.

Ford’s commitment to innovation went beyond engine selection. Ford’s engineering team, led by Roy Lunn, had growing concerns about the limitations of the GT40’s original 4.7-liter engine and its Colotti transmission. To address these issues, Ford established Kar Kraft, a dedicated subsidiary tasked with designing advanced racing components.

The first project at Kar Kraft was a new, more robust transmission capable of handling the GT40’s power without compromising reliability. This was crucial, as transmission failures had been a recurring issue in earlier GT40 models.

The combination of a powerful V8, a new transmission, and meticulous engineering allowed the GT40 Mk II to outperform Ferrari’s V12-powered cars. It was a pivotal moment not only for Ford but also for American motorsports, proving that American innovation and performance could take on—and beat—the world’s best.

Ford’s triumph with the GT40 Mk II at Le Mans is a story of strategy, power, and persistence—a testament to what can be achieved when engineering meets an unyielding desire to win.

In early 1965, Kar Kraft, Ford’s specialized racing division, embarked on a daring project to modify two GT40 chassis to fit the massive 7.0-liter Ford Galaxie engine. Initially, these powerful builds weren’t even intended for Le Mans due to handling concerns.

However, advances in tire technology soon allowed for stable, high-speed handling, prompting test driver Ken Miles to clock an impressive 201 mph at Ford’s Romeo, Michigan, track. This unexpected performance led to a bold decision: these modified GT40s would indeed race at Le Mans.

Despite their determination, Ford’s inexperience at Le Mans became apparent. The team missed the critical April practice sessions with the 427-powered cars, and in a scramble, completed the second GT40 just in time for the race itself.

Unfortunately, rushed preparation took its toll, with both cars facing mechanical setbacks—a scrap gear mistakenly installed in one transmission and debris on a bearing surface in the other, resulting in both Kar Kraft-developed gearboxes failing during the race. While disappointing, the experience offered key insights, especially regarding the potential of the 7-liter V8 for endurance racing.

Ford’s chief engineer, Roy Lunn, walked away from the 1965 race with a crucial realization: the GT40’s big engine, operating at a modest 6,000 rpm, provided both power and reliability. This lesson paved the way for future GT40 success, demonstrating that the right combination of engineering innovation and bold strategy could one day secure Ford’s dream of a Le Mans victory.

Contents

Ford’s Winning Strategy For Le Mans

In 1966, Ford’s drive for Le Mans victory took a major leap with a new multi-team strategy that reshaped their racing approach. Racing manager John Cowley spearheaded this transformation by bringing three dedicated teams—Shelby American, Holman-Moody, and Alan Mann Racing—to the table, creating an environment of intense but constructive competition. Cowley, alongside development engineers Homer Perry and Chuck Folger, provided coordinated oversight across teams, ensuring each team’s insights were shared for continuous improvement.

Ford’s strategy involved rigorous vehicle testing across diverse locations like Daytona, Sebring, Riverside, and Ford’s Kingman proving ground in Arizona. Cowley’s team, now working more collaboratively than ever, made invaluable progress, fueled by the expertise of Holman-Moody, a stock car outfit that surprised skeptics with its engineering prowess and raised the bar for Shelby American. Their input led to critical advancements that strengthened Ford’s Le Mans effort, as well as the coordination skills needed to unify racing teams with distinct philosophies.

Adding to this successful structure was Ford’s Le Mans Committee, a dedicated group of high-level staff from various divisions (Engine & Foundry, Transmission & Chassis, and Ford Division) who regularly reviewed goals and solved shared challenges. This collaborative push by Ford’s leadership—featuring Donald Frey (VP and general manager), Leo Beebe (director of racing activity), and Jack Passino (manager of Special Vehicles Activity)—ensured a singular focus on winning at Le Mans, transforming Ford’s racing program into a formidable, finely tuned operation.

This robust organizational effort, backed by Kar Kraft’s prototype designs and top-notch engineering from Ford’s racing partners, resulted in a unified Le Mans mission that would ultimately change racing history and leave an indelible mark on Ford’s racing legacy.

The Development Of The Ford GT40 Mark II: Power Meets Precision

After the 1965 Le Mans, Ford saw the potential in their Mark II GT40 to be a competitive force for 1966. Yet, the challenge was not just speed—it was ensuring reliability for the grueling 24-hour race. The Mark II shared its roots with the original GT40, designed by Eric Broadley and later refined by Roy Lunn’s engineering team.

Modifications for the Mark II included a larger 7-liter V8 engine, adding significant weight to the car and requiring an extended nose for improved radiator space, along with new cast alloy wheels to replace the original wire wheels.

The Mark II retained a conventional GT layout with a midship engine, semi-monocoque chassis, and independent suspension, but Ford’s big-block V8 set it apart. Ford engineers were committed to the 427 V8, a powerful and proven engine well-suited to NASCAR but rarely used in endurance racing.

This big V8 allowed for high torque without requiring the high-rev stress of smaller, lighter engines, but it also introduced new engineering challenges. The engine’s weight increased stress on transmission components and suspension, particularly at high-speed circuits like Daytona.

Aerodynamic stability became another focus, especially with the extended nose, which added downforce to the front but caused rear-end instability. This resulted in the iconic look of the 1965 Mark II with its array of fins and tabs to keep it grounded. Ford’s engineers now had the time to address these issues through a comprehensive development program—optimizing brakes, refining suspension, and enhancing aerodynamics to prepare the Mark II for the demands of Le Mans.

The Mark II’s evolution embodied Ford’s commitment to building a car capable of competing with the best, marking a pivotal moment in American racing history and setting the stage for Ford’s victory in 1966.

Ford GT40 Engine Development For Le Mans Victory

As Ford refined its 7-liter pushrod engine for the GT40’s Le Mans campaign, engineer Gus Scussel led a weight reduction effort at Ford’s Engine & Foundry Division. By incorporating aluminum heads, an aluminum vibration damper hub, and a lightweight water pump, the Le Mans version of the engine weighed in at 550 lbs—52 lbs lighter than the NASCAR counterpart. Despite this lighter build, the GT40’s engine maintained durability, a crucial factor for the 24-hour endurance race.

Ford engineers prioritized rpm control to protect the engine’s longevity, capping it at 6200 rpm to prevent excess strain, though it was capable of hitting 7400 rpm for short bursts. To ensure drivers stayed within limits, tachs were precisely calibrated, and each car had a detailed calibration chart on the driver’s door. In addition to rpm control, the compression ratio was dialed down to 10.5:1 to handle the 101-octane fuel available at Le Mans, with aluminum heads improving heat dissipation.

The dry sump system was redesigned to include dual scavenge pumps and an effective oil cooler, critical for keeping engine temperatures in check during intense racing conditions. Another modification was the single 4-barrel Holley carburetor, chosen for its simplicity and efficiency, though it was unique among the multiple Webers on competing cars. Through a thorough dynamometer durability test cycle, Ford simulated the track’s demands, pushing the engine through 48 hours of operation at realistic race speeds. This ensured that come race day, durability was a certainty.

In Le Mans configuration, the engine produced 485 bhp, less than the 520 bhp NASCAR version but perfectly suited for endurance racing. Its output of 69 bhp per liter was modest by performance standards but compensated with unmatched reliability, delivering consistent power from as low as 1000 rpm in top gear. Ford’s GT40 engine was a testament to engineering efficiency, transforming a stock V8 into a race-winning machine that cemented the GT40’s legendary status at Le Mans.

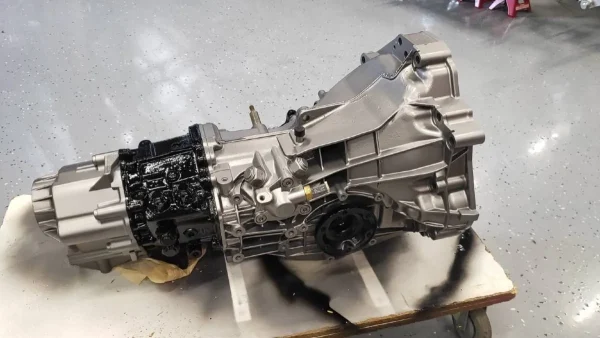

Transmission Development – Big Engineering Achievement

The Ford GT40’s transmission design was a key factor in harnessing the massive torque from its 427-cubic-inch V8 engine. The team at Kar Kraft engineered a custom transaxle assembly to meet the high torque demands while ensuring reliability on the track. This light-alloy encased unit used heavy-duty Ford gears and shafts to ensure durability during the grueling endurance races.

At the heart of the GT40’s transmission system is a Long 2-dry-plate clutch with 10-inch diameter plates that seamlessly transmits torque to the gearbox’s input shaft. From there, a standard 4-speed synchronized gearset manages gear changes, while a specialized set of transfer gears fine-tunes the final drive ratio to optimize performance for different tracks.

For the Le Mans Mk II, a 0.899:1 transfer gearset produced a final drive ratio of 2.77:1, ideal for the long, high-speed straights of Le Mans. The four gearbox ratios included 2.22, 1.43, 1.19, and 1.00:1, providing the perfect balance between acceleration and top speed.

Kar Kraft also began experimenting with automatic transmission prototypes. They explored two designs: a 2-speed with a torque converter and manual shifting, similar to the Chaparral unit, and a bulkier, “power-shift” transmission with full-power upshifting and downshifting.

The “power-shift” used hydraulic disc clutches and oil pressure, controlled by the driver’s lever, to allow shifts without throttle lift. This unit was tested at Daytona and Sebring with promising results, though development continued to meet Lunn’s standards for power efficiency.

These innovations underscored Ford’s commitment to enhancing performance through transmission technology. With every component tailored for endurance racing, the GT40’s transmission system was as legendary as its engine, delivering the torque needed to conquer the 24 Hours of Le Mans and secure its place in racing history.

Chassis And Suspension: Precision Engineering For Maximum Performance

Ford’s enhancements to the GT40 chassis and suspension focused on strength, convenience, and handling superiority. Structural modifications, driven by rigorous testing at Daytona, improved durability by reinforcing engine mounts and A-arm pivot areas with additional gussets.

The front A-arms were enlarged for extra strength, while new front upright castings gained thicker walls and internal ribs for durability. To optimize control, the rear upper control arm pivot was now supported at both ends, with adjustable control arm lengths allowing for quick on-track adjustments.

The chassis upgrades resulted in remarkable torsional rigidity at 10,000 lb-ft/degree, setting a new standard for endurance racing stability. Shelby American led much of this development work, crafting wheels with heavily reinforced spiders to meet the demands of high-speed endurance racing.

Ford’s edge in handling and aerodynamics gave the GT40 a lead over competitors like Ferrari and Chaparral, despite their power-to-weight advantages. Ford’s wind tunnel testing at 130 mph and real-world trials at 200 mph fine-tuned the GT40’s aerodynamics. Unlike typical suspension systems of the era, Ford employed computer-assisted suspension geometry refinement, enabling rapid adjustments that maximized handling precision far beyond traditional methods.

The GT40 also benefited from Koni double-adjustable shocks, replacing the Armstrong units previously used, allowing separate adjustments for jounce and rebound. Combined with a 95-inch wheelbase and a widened front tread, the GT40 achieved superb handling balance, crucial for endurance racing.

This engineering marvel wasn’t built on revolutionary ideas alone but on Ford’s unmatched resources in testing and precision refinement. The result? A GT40 chassis and suspension system meticulously engineered to dominate, making Ford’s GT40 a true legend in Le Mans history.

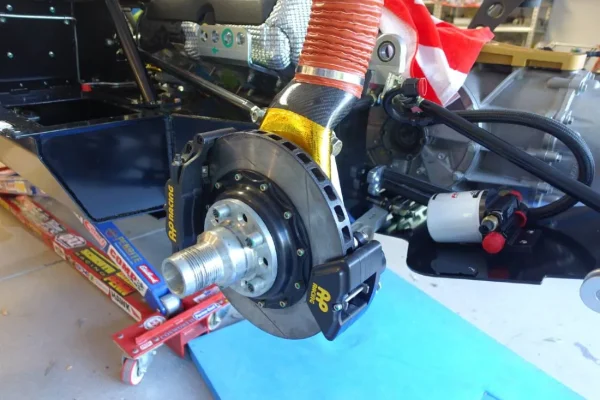

Brakes Are Engineering Solutions For Endurance Racing

The Ford GT40’s braking system faced ongoing challenges due to the intense demands of endurance racing. Brakes remained a primary focus for improvement, with Ford and Shelby American engineers working to address issues such as rotor cracking and pad wear.

The vented, radial-spoked rotors used previously often cracked under stress, leading to the adoption of curved spokes in 1966 to help reduce failures. However, the limitations of the 11.6-inch rotors and 653 square inches of swept area left no room to expand the disc or pad size.

To tackle the issue, engineers concentrated on developing solutions for fast replacement of brake components during races. Shelby American’s Phil Remington designed quick-change brake pad retainers that allowed rapid pad swaps, reducing pit time.

Additionally, John Holman from Holman-Moody introduced an innovative quick-change rotor system that allowed for even faster replacements—a revolutionary feature in racing. This new system used a unique design where the disc hats sat outboard of the hub flange, secured by wheel studs, making it possible to remove and replace the rotors in seconds after the caliper was loosened.

The GT40’s braking system used Girling BR single calipers front and rear, retaining a simple yet powerful configuration that combined durability with ease of access. The quick-change solutions ensured that, despite limitations, Ford’s GT40 could compete effectively without losing valuable seconds in the pits.

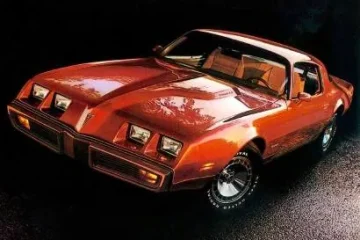

Body Design Is Amazing Aerodynamics And Functionality Perfected

The Ford GT40 Mk II features significant bodywork enhancements over its predecessor, the Mk I, aimed at optimizing aerodynamics, weight reduction, and cooling efficiency. Only the midsection retains the Mk I design, while both the front and rear sections are entirely new.

These changes showcase how effectively Ford and Shelby American engineers applied wind tunnel testing to refine performance, achieving a streamlined design that eliminated the need for add-ons like fins and tabs. An adjustable rear spoiler, positioned between 1.5 and 3 inches, is the only aerodynamic adjustment added to suit different drivers’ preferences.

The most visible transformation is the front-end design, now shortened by 9 inches. This new nose, based on a “production” GT40 with raised fender humps, lowers the car’s center of pressure while providing more wheel travel, ultimately contributing to improved handling and stability. This shift in the front also removed the need for rear fins and saved 19 pounds, enhancing the car’s agility and balance.

Cooling requirements were meticulously addressed through a redesigned duct system. Wind tunnel analysis helped determine optimal duct placement, with each scoop carefully positioned for specific cooling functions:

1. Low right-side scoop for transaxle cooling.

2. Low left-side scoop for engine oil cooling.

3. High side scoops on both sides, with upper portions dedicated to carburetor cooling and lower sections directing air to the brakes.

4. Top deck scoops—added during the Sebring tests—for brake cooling.

Hot air from the engine bay is further managed by louvers on the rear deck, which channel airflow over the exhaust, aiding in heat dissipation. This updated tail structure, weighing 37.5 pounds compared to the former 80-pound setup, reinforces the GT40’s streamlined approach, enhancing overall performance.

Convenience also improved, with a new access panel in the nose allowing quick access to the spare tire and oil tank without lifting the entire front end—a detail that underscores Ford’s commitment to functionality as well as speed.

Driving Impressions By Ken Miles: Power And Precision On The Track

Renowned driver Ken Miles described the Ford GT40 Mk II as an extraordinary machine—one that’s easy to drive when perfectly tuned but challenging when not, typical of high-performance racing cars. According to Miles, minor adjustments in the chassis tuning dramatically alter the Mk II’s handling, making precision in setup crucial. For example, at Le Mans, Miles and his team fine-tuned the rear spoiler to a 2-inch height to achieve optimal stability.

The GT40 Mk II’s engine is remarkably flexible, allowing Miles to lug it down to 1000 RPM in fourth gear and still deliver power smoothly. Although the engine’s redline is 7400 RPM, Miles kept it under 6200 RPM during races to ensure reliability, which helped the team handle the car’s immense torque effectively. This impressive durability demonstrates the Mk II’s engineering, balancing high performance with sustained longevity.

Comfort is surprisingly decent for a race car. Though the cockpit can become extremely hot, and the steering is notably heavy, the seating remains supportive and ergonomic, keeping drivers comfortable during extended races. However, visibility remains a challenge, with rearview mirror adjustments required on the fly, and the windshield wipers effective at high speeds but limited in function by the washer system.

Driving the GT40 Mk II demands skill due to the high-effort brakes, which operate at a blistering 1650°F, limiting their effectiveness despite structural reinforcement. Braking reliability became a challenge at Le Mans, where Miles had to schedule his driving for minimal brake disc changes—yet even then, one faulty disc required an additional pit stop.

The throttle linkage design allows for smooth and progressive power delivery, though Miles finds the suspended pedal somewhat awkward. Acceleration from 3000 RPM is astonishing, feeling even more powerful than expected for a car with Galaxie-based internals and a robust gearbox.

Despite the engine’s roar, noise levels are surprisingly tolerable, similar to those in a street Cobra. The GT40 Mk II is a true marvel in motorsport, providing race-ready power with an uncompromising approach to track performance and driver engagement.

Ford GT Mk II: The Powerhouse Of American Engineering At Le Mans

The Ford GT Mk II stands as a testament to American engineering in endurance racing. Originally designed in England, the Mk II has evolved into an American powerhouse, showcasing a distinct approach compared to its European competitors.

Unlike the lightweight, high-revving engines of European sports cars, the GT Mk II packs a heavy-duty, large-displacement engine with Ford’s signature design. This configuration proved to be incredibly competitive in long-distance races, shattering expectations by dominating Le Mans and rivaling Europe’s finest in sheer performance and durability.

As Ford looks to the future, the next step in this racing journey is the development of the Ford J-Car, a refined evolution of the Mk II. Purpose-built with insights from years of GT40 advancements, the J-Car includes a revolutionary honeycomb aluminum underbody, reducing weight dramatically from the Mk II’s 360-pound steel frame to just 169 pounds. This structural leap forward not only lightens the car but improves performance, making it a formidable contender for upcoming races.

Pioneering the path for the J-Car, Ken Miles and Lloyd Ruby tested an open prototype at Sebring, which demonstrated the viability of the lightweight aluminum underbody. With support from dedicated teams at Ford Dearborn, Shelby American, Alan Mann Racing, and Holman-Moody, there’s optimism across the board for the J-Car’s future success.

As the Ford racing budget decisions unfold, enthusiasts and engineers alike are hopeful for the green light to continue pushing the boundaries of American sports car engineering on the world stage.

What’s The Fascinating History Of The 1966 Ford GT40?

The 1966 Ford GT40 was born from Henry Ford II’s vision to defeat Ferrari at Le Mans. After years of development, the GT40 Mk II triumphed, securing a 1-2-3 finish at the legendary 24-hour race. Key to its success was a durable 7.0-liter V8 engine, strategic teamwork, and engineering precision, propelling American automotive engineering to a historic victory.

0 Comments